Vogel Tube Bending

Exceptionally strong in tube bending

Are you looking for a professional partner for all your tube bending needs? You will find that partner in Vogel Tube Bending. We have decades of experience in the field of metal processing and work in a sustainable and high-quality manner. We are eager to work with you towards a better future for your company, people and nature.

The foundation that makes us the specialist in tube bending

Thanks to our solid foundation, we have been a specialist in tube bending and other metal processing operations for over 50 years. Nevertheless, we strive to expand our expertise every single day. We achieve this by continuously investing in new machinery, which means we now have an extensive machine park supported by our modern laboratory.

We also invest in training people and collaborating with specialists within our industry. This furthermore promotes another goal of ours: preserving the manufacturing industry in the Netherlands and Western Europe.

The continuous process of self-improvement has been driven by the entrepreneurial spirit of the founder and his successors for years. Through this approach, we can continue to work with you on solutions and deliver high-quality tube bending.

Below you can read about the industries we serve and the certifications we hold for our quality processes!

We deliver certified services for various industries

Our quality management complies with the ISO 9001:2015 standard. This standard indicates that we deliver our work on a continuous basis with high customer satisfaction. In our view, this demonstrates that we understand customer requirements well. With the help of our expertise, we are able to execute your project through one of our services.

In addition, we also hold the IATF 16949:2016 certificate. This demonstrates that our metal processing meets the quality standards of the automotive industry. The fact that we hold this certificate means that our tube bending and assembly meet the requirements in the areas of design, development, production, installation and maintenance established by the automotive industry.

By adhering to these high standards, we can deliver tube bending, welding, soldering and assembly services to many industries.

Mission

Years of experience and passion for technology enable us to deliver cost-effective and high-quality work. Continuous self-reflection and flexible cooperation lead to customer-focused solutions and sustainable relationships.

Vision

Expanding the company by establishing long-term and sustainable relationships with customers and suppliers.

The origin of Vogel Tube Bending and our core values

The family business Vogel Tube Bending was founded in a backyard shed in 1951. Initially, the focus was not yet on tube bending and the manufacturing industry, but on potato starch and straw cardboard.

The shift in focus occurred in the 1970s. Initially, we mainly supplied components for gas boilers, central heating boilers and heating systems. However, other sectors such as the automotive, bus and agricultural sectors were soon added. Since then, we have grown into a true specialist in the field of tube bending, such as cold mandrel bending, rolling, forming and processing ferrous and non-ferrous tubes, profiled tubes and profiles. We can also assemble these metals, for example through soldering or welding. Moreover, rolling is also one of our specialties.

In addition, our standards and values have also contributed to the growth of our company. Our down-to-earth approach ensures that we always remain attentive in our cooperation with our clients. This makes us a reliable and solution-oriented partner who works flexibly and with quality, never losing sight of people, surroundings and the environment.

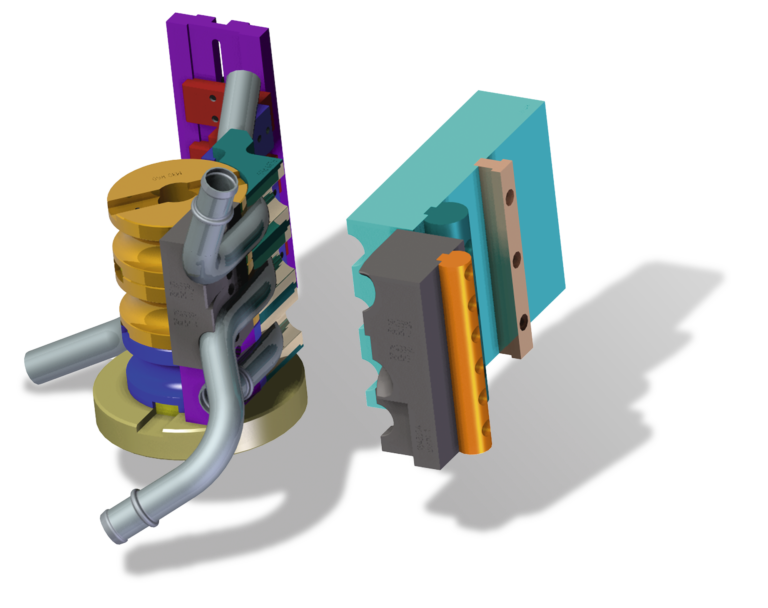

From design to prototype to series product!

Our working method is designed to put the customer first and to enable us to respond flexibly to changing customer requirements. We want to make a significant technological contribution together with the customer. For the development and production of new products, we therefore use the APQP (advanced product quality planning) principle as a guide. A process that corresponds with the DFSS (design for six sigma) trajectory.

We have our own tool-making facility. Because we can make new tools for all tube bending work, we are able to fulfil almost all customer requirements. The guideline in the translation process from customer requirement to end product is always accompanied by the use of our 3D CAD software.

Finally, we are able to translate your products into a 3D and 2D drawing model using 3D optical measuring equipment. In this way, we can also produce your prototypes without you having to provide drawings in advance.

Are you curious about what metal processing operations, such as tube bending, we can perform for you? Please feel free to fill in our contact form!